Four ways to a clean gasoline engine

More and more people desire mobility. Especially in big cities packed with cars, this has a negative impact on air quality. BASF’s FWC™ four-way conversion catalyst is a trailblazing technology for reducing pollution from gasoline-powered combustion engines. Particles are filtered out of tailpipe emissions in addition to gaseous pollutants.

Three plus one equals four

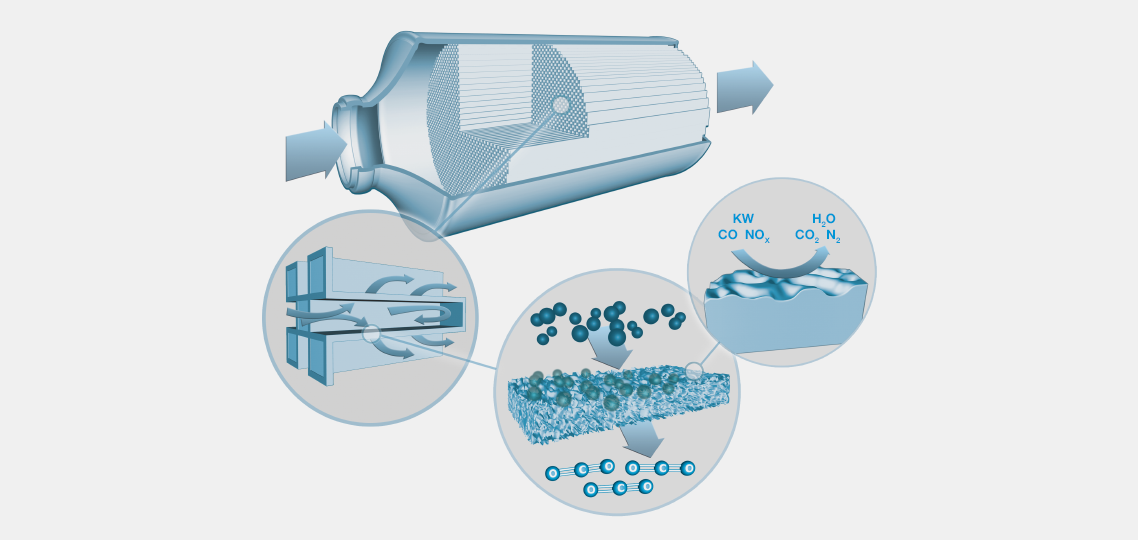

The conventional three-way catalyst for gasoline engines can eliminate pollutants like nitrogen oxides, carbon monoxide and unburnt hydrocarbons from tailpipe emissions. In order to remove carbon particulates, a separate filter must be added. This requires additional space and can increase back pressure on the flowing exhaust gas, putting a strain on engine performance and increasing fuel consumption.

BASF researchers have developed the three-way conversion catalyst into a four-way conversion catalyst, or FWC™, that combines all important features into a single engine component. This helps automotive manufacturers comply with more stringent emissions regulations, such as Euro 6c, without having to install a separate gasoline carbon filter.

Compact and effective

Designed for gasoline engines, the FWC™ consists of a ceramic filter coated with catalytically active precious metals, filtering both gaseous pollutants and carbon particles out of exhaust flow. This means it takes up considerably less space than a three-way conversion catalyst with a downstream filter.

BASF’s innovative production and coating technologies keep the back pressure on exhaust gases low. And because the carbon particulate matter is incinerated into carbon dioxide at high temperatures, the catalyst’s pores cannot clog up, giving the component long-lasting durability.