Our Strategic Action Areas

BASF’s strategic orientation is founded on a comprehensive analysis of our markets, competitors and the economic environment. We continuously monitor global trends and short-term developments and anticipate the resulting opportunities and risks. The following six strategic action areas enable us to focus on our customers while strengthening our leading position in a competitive environment.

Innovation

Innovation is the bedrock of our success. BASF is a leader in the chemical industry with around 10,000 employees in research and development and R&D spending of around €2.3 billion. We want to expand this position by strengthening our research activities, especially in battery materials, polymer technologies and catalytic and biotechnological methods (see box on the right). In addition, we are expanding our cooperation with customers, universities, research institutions and other partners.

We reorganized our global research activities in 2022. Business and application-driven units that were previously part of three research divisions were integrated into the operating divisions, aligning them more closely with the needs of our customers. For greater efficiency and effectiveness, we have bundled research activities that are relevant to several operating divisions in the new cross-functional and cross-regional Group Research unit. This global research division supports our operating divisions’ customer-specific R&D activities. It also drives forward cross-divisional projects on topics relevant to the entire Group, such as avoiding CO2 in chemical processes and products, energy efficiency and recycling technologies.

Our innovation pipeline is geared to sustainability – especially climate protection and the circular economy. This lays the foundation for future growth: We are working intensively on fundamental innovations for products, processes and business models, for example, for the chemical recycling of plastics, battery and catalyst technologies, low-carbon production of basic chemicals, and digital, climate-smart farming. At the same time, we are developing product improvements in all business units that offer our customers sustainability and competitive advantages. These include surface solutions for the aviation and wind power industries, bio-based and biodegradable active ingredients for the cosmetics, detergent and cleaner industries, and engineering plastics based on renewable raw materials.

Good to know

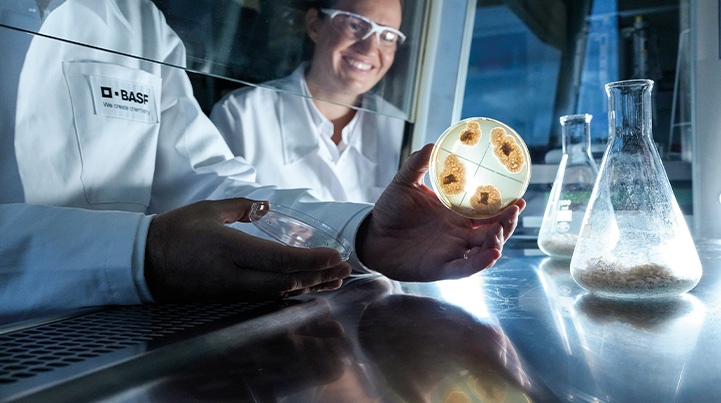

Driving sustainability with microorganisms

With its broad technological expertise, BASF is well positioned to develop innovative solutions for a sustainable future. One of our key technologies is white biotechnology. White biotechnology enables us to produce a wide range of products using a variety of feedstocks in an efficient, resource-conserving and flexible manner: biopolymers, essential ingredients for human and animal nutrition, crop protection products, flavors and fragrances, or ingredients for cosmetics. We also produce enzymes from fungi and bacteria for use in detergents. One example is BASF’s protein-cleaving enzyme Lavergy® Pro, which removes tough stains even at low temperatures and in short wash cycles, thus saving energy and water.

Microorganisms are not just used to manufacture products, but at the end of the product life cycle as well. We are working to understand how microorganisms metabolize complex organic compounds into energy, water, carbon dioxide and biomass. A fundamental understanding of such biological processes is needed to use this natural method and develop biodegradable products. In addition, digital tools are an important component of the research work to predict the properties and biodegradability of molecules and materials at a very early stage of product development, enabling their structures to be adapted accordingly. This is important for products that end up in wastewater treatment plants at the end of their life cycles, such as cosmetics, laundry detergents and dishwashing products. Another example is our certified biodegradable biopolymer ecovio®. This can be used to produce mulch films that can be plowed under after use in the field and completely metabolized by microorganisms.

Sustainability

We believe that the economy, environment and society are inextricably linked and interrelated. We want to create value in all three areas with our products, solutions and technologies. We pledged our commitment to sustainability in 1994 and since then, have systematically aligned our activities with the principles of sustainability. We want to further strengthen our position as a pioneer for sustainable solutions. We see sustainability as an integral part of our strategy as well as our targets, steering processes and business models. In doing so, our aim is to be a responsible and attractive partner for our customers, develop new growth areas and lay the foundation for the long-term success of our company. Our approach covers the entire value chain – from the responsible procurement of our raw materials and safety and resource efficiency in production to sustainable solutions for our customers.

Protecting the climate is of central importance for us here. Since 1990, we have more than halved our carbon emissions while simultaneously doubling sales product volumes. By 2030, we want to reduce our absolute CO2 emissions by 25% compared with 2018 and will invest up to €4 billion to this end. By 2050, we aim to achieve net zero greenhouse gas emissions from our production sites and our energy purchases. We are pursuing ambitious climate protection targets with our carbon management. This comprises five strategic levers that we are systematically driving forward to reduce our greenhouse gas emissions.

In the future, we want to align our product portfolio even more strongly with climate protection, carbon neutrality and circularity in order to meet the growing sustainability demands in our markets with innovative solutions. That is why we are updating our Sustainable Solution Steering methodology for steering the product portfolio based on sustainability criteria (see Our Sustainability Concept). We will apply the new methodology for the first time in the 2023 business year. In addition, a digital solution enables us to calculate the carbon footprint of our approximately 45,000 sales products – from raw materials extraction to the factory gate (“cradle-to-gate”). This creates transparency around the carbon intensity of our products and at the same time provides important starting points for reducing greenhouse gas emissions along our value chains.

- More information on energy and climate protection and our carbon footprint

- More information on the circular economy

Production

Our core business is the production and processing of chemicals. Our strength here lies in the Verbund and its integrated value chains. This enables us to achieve efficient, reliable and CO2-optimized production and leverages synergies in the development and application of new technologies and the use of digital solutions. At the same time, the Verbund is the foundation for meeting the increasingly diverse needs of our customers and markets with a differentiated offering. Our comprehensive product portfolio ranges from basic chemicals to custom system solutions.

Our strategy is to produce locally for local markets, close to our customers. We plan to invest €28.8 billion worldwide between now and 2027 to expand our capacities based on market demand and to further increase the availability, efficiency and flexibility of our plants. In particular, we want to benefit from the strong growth of the chemical market in Asia (see “Portfolio”). Our global production footprint contributes to the regional diversification of our sales and earnings distribution, making it part of our risk management. It helps us to compensate for economic weaknesses and a lack of growth prospects in individual markets within the BASF Group. This currently applies to Europe and especially Germany, where high natural gas prices and a challenging regulatory environment are negatively impacting our competitiveness and our growth.

Digitalization

We want to leverage the diverse growth potential of digitalization, seize the associated opportunities to the benefit of our customers and strengthen our competitiveness. To achieve this, we promote digital skills among our employees, cooperate with partners and make digital technologies and ways of working an integral part of our business.

Digitalizing our plants and systematically analyzing data enables us to further automate processes and in this way, manage the capacity, availability and efficiency of our plants in line with market conditions, for example, by simulating value streams within our Verbund structure or through predictive maintenance. Linking data from different sources and using artificial intelligence for smart data analysis opens up numerous opportunities for us to manage our business more efficiently and improve our processes, for example, in logistics.

The combination of products, services and digital offerings also creates new business models and advantages for our customers, such as in agriculture or the personal care industry. In addition, digitalization enables us to further strengthen our innovative power. BASF has one of the most powerful supercomputers in the chemical industry – Quriosity. We use it to accelerate complex computing processes such as the simulation of molecules, for example. At the same time, we are working on groundbreaking technologies such as quantum computing, including as a founding member of the Quantum Technology and Application Consortium (QUTAC). We are also involved in other digitalization initiatives such as the Catena-X network, where we are working with partners to develop a system for standardized data exchange in the automotive value chain.

Portfolio

We are orienting our portfolio even more strongly toward innovation-driven growth areas with high Verbund synergies. Following major acquisitions (battery materials, engineering plastics, farming solutions) and divestitures (pigments, construction chemicals, paper and water chemicals) in recent years, we continued on this course in 2022 with divestitures and division-specific partnerships. As planned, we divested the kaolin minerals business to KaMin and the attapulgite business to Clariant.

At the same time, we are strengthening the basis for our organic growth with investments. In North America, for example, we launched the third and final phase of the MDI expansion at the Geismar site in Louisiana in 2022. Examples in Europe include the construction of a new hexamethylenediamine (HMD) plant at our site in Chalampé, France, and the expansion of our polyamide 6.6 production in Freiburg, Germany. A new world-scale production plant for alkylethanolamines will be built at the Verbund site in Antwerp, Belgium, by 2024. The Asian market will play a key role in our future growth. With a share of more than 45%, China is already by far the world’s largest chemical market and is a key driver of growth in global chemical production. We have a strong production, sales and innovation base in Asia, and in particular in China, which we will continue to expand. Our largest project is the new Verbund site in Zhanjiang in the southern Chinese province of Guangdong. We granted final approval for its construction in 2022. Once completed, it will be BASF’s third-largest Verbund site after Ludwigshafen, Germany, and Antwerp, Belgium. Following the successful startup of the first plant for the production of engineering plastics in August 2022, the focus in Zhanjiang is now on the step-by-step establishment of the Verbund structure, starting with the construction of a steam cracker along with downstream plants for the production of petrochemicals and intermediates. Work is also underway to complete a plant for thermoplastic polyurethanes and to build a plant for neopentyl glycol. In addition, the expansion of our Verbund site in Nanjing, China, operated together with Sinopec, started operation in 2022. New plants for products from the Petrochemicals and Intermediates divisions will be built there by the end of 2023.

We also further expanded our global battery materials business in 2022. This includes investments to increase our production capacities and to establish innovative recycling concepts in the three key regions of Europe, North America and Asia. At the Schwarzheide site in Germany, we started the multi-step commissioning process for a new production plant for cathode active materials1 at the end of 2022, as planned. We are also building a prototype plant for battery recycling in Schwarzheide,1 which is scheduled for startup in 2023, as well as a plant for the production of black mass from batteries on a commercial scale (planned startup: 2024). We are working on the integration of our production site in Harjavalta, Finland,2 which supplies precursors for cathode active materials. Alongside our existing sites in North America, we are looking into investing in a new production site for cathode active materials and battery recycling in Bécancour, Canada. The new site allows for ample space to expand up to 100 kilotons of cathode active materials per year with potential for fully integrated precursor cathode active materials supply. We are also currently expanding the capacity of BASF Shanshan Battery Materials Co., Ltd. in China to 100 kilotons per year. The multi-step commissioning process for the new production lines at the Changsha and Shizuishan sites started in late 2022 as planned. In Onoda, Japan, work to expand production capacities for cathode active materials at BASF TODA Battery Materials LLC has also been underway since the end of 2022. This is scheduled for startup in the second half of 2024. Our production facilities in all key regions and growing capacities enable us to serve battery cell and automotive manufacturers in all relevant markets even more extensively with tailored and sustainable solutions.

Employees

Our employees are key to BASF’s success. That is why we believe that it is important to have an attractive total offer package and an inspiring working environment that fosters and develops employees’ individual talents and enables them and their teams to perform at their best. We are pursuing three action areas to make our high-performance organization even more so: empowerment, differentiation and simplification of structures and processes. At the same time, we encourage and promote a leadership culture that empowers our employees to respond to customer needs quickly and efficiently with a solution orientation. We value diversity in people, opinions and experience as being crucial to creativity and innovation. We embrace bold ideas, help our employees to implement them and learn from setbacks. This is founded on an open feedback and leadership culture based on mutual trust, respect and dedication to top performance.

1 Our investment and research activities in Schwarzheide and Ludwigshafen, Germany, receive funding from the German Federal Ministry for Economic Affairs and Climate Action and the Ministry for Economic Affairs, Labor and Energy of the German state of Brandenburg under the IPCEI on Batteries (funding code 16BZF101A/B).

2 The investment in Finland is co-financed by Business Finland, the Finnish government organization for innovation funding and trade, travel and investment promotion.