Innovation in the segments – examples

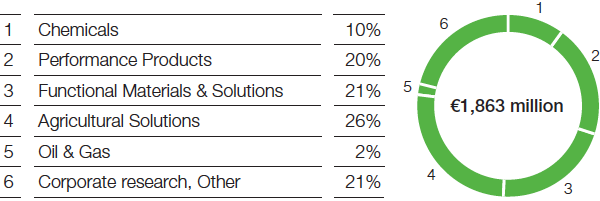

Research and development expenses by segment

Chemicals

In 2016, we established the Amsterdam-based Synvina C.V. joint venture with Avantium to produce and market furandicarboxylic acid (FDCA) from renewable resources on an industrial scale. The most significant use of FDCS is the production of polyethylenefuranoate (PEF), a new polymer used for applications such as food and beverage packaging. Compared with conventional plastics, PEF demonstrates higher barrier properties for gases like carbon dioxide and oxygen, leading to a longer shelf life for packaged products. In addition, its higher mechanical strength allows for thinner – and therefore lighter – packaging.

Our new HydroBlue®90 demonstrates that innovation and enhancement are even possible for products that were patented over 100 years ago. The product originally went to market as an auxiliary agent in dyeing textiles with indigo. Today, HydroBlue®90 ensures consistent high quality in the dyeing process. This stability is important for textile producers, as signs of faulty coloring in denim do not usually appear until after the garment is already finished. New HydroBlue®90 is especially highly concentrated, shelf-stable, odorless and dust-free.

With Ultramid® C37LC, BASF launched a new, high-quality copolyamide on the market in 2016. It ensures a stabler and more efficient production process for shrink films used in food packaging. Films produced with Ultramid® C37LC are considerably softer and more transparent than those made from conventional materials. Manufacturers of fishing nets and lines can also further increase the quality of their products using the new plastic.

Performance Products

Flexible food packaging must fulfill the highest functional requirements; at the same time, interest is growing in environmentally friendly solutions. That is why we are constantly enhancing the ink bonding agents of our Joncryl® FLX product line and the laminating adhesives of the Epotal® range. These water-based products provide a more environmentally friendly alternative to solvent-based systems for flexible packaging. With Epotal®, packaging manufacturers can also shorten the processing time between order placement and delivery.

Lavergy® Pro 104 L is a newly developed protease – or protein-splitting enzyme. Liquid detergents formulated with this enzyme are already powerfully effective at low washing temperatures, removing certain tough stains considerably better than the established market standards. Lavergy® Pro 104 L is even more powerful when combined with our high-performance detergent polymer Sokalan® HP 20. Expertise in both biology and chemistry allows us to offer customers even more opportunities to precisely customize liquid detergent formulations.

Farmers require high-quality feed for their animals. Yet preserved feed, typically in the form of silage, and water are both susceptible to pathogenic microorganisms. Adding our Lupro-Mix® NA organic acid mixture inhibits the growth of harmful bacteria and mold, allowing livestock to receive silage and water of the highest quality. Farmers also benefit from the fact that Lupro-Mix® NA is easier and safer to use than comparable products, while remaining nevertheless economical.

Plastic components offer possibilities to make vehicles lighter, more comfortable, and more aesthetically pleasing. Additives like light stabilizers are used to maintain the original properties and appearance of materials and surfaces for as long as possible. Tinuvin® 880 is a novel light stabilizer that significantly increases the durability of plastic parts exposed to UV radiation and heat, making it suitable for automotive applications that require plastics to stand up to high levels of stress. Tinuvin® 880 can also be used in the construction, agricultural and packaging industries.

Functional Materials & Solutions

To meet ever-tightening exhaust regulations for diesel vehicles, manufacturers employ special catalysts for nitrogen oxides (NOx) such as lean NOx trap (LNT) technology, that is, NOx adsorbers. With EMPRO® LNT, BASF has launched a new generation of these catalysts that are especially robust and powerful, even under widely various driving conditions, like city traffic, country roads, or interstate highways.

MasterSuna SBS is a new concrete additive that allows previously unsuitable types of sand to be processed into high-grade concrete. Clay minerals in sand usually prevent concrete superplasticizers from doing their job. With MasterSuna SBS, even sand containing high levels of clay can be used in the production of consistently high-quality concrete. Concrete producers save considerable costs, as they no longer need to pay for the transport of more suitable sands from distant sand pits. Fewer sand pits need to be opened, as well, which helps protect the environment and landscape.

Our Cool Coatings automotive coating technology combines innovative functional properties with a sophisticated design that allows for a broad color palette. The coating formulation reflects infrared light, reducing the vehicle’s surface temperature by up to 20°C. This passive temperature management reduces the inside temperature by up to 4°C. Cool Coatings thus enables our customers to save on air conditioning, which decreases fuel consumption or, in the case of electric vehicles, increases range.

Ultramid® Advanced N, our new portfolio of heat-resistant polyamides, gives customers in different industries greater freedom for innovation, such as when it comes to developing technically sophisticated end-user products. It allows for the construction of lighter, smaller and more high-performance plastic components for demanding operating conditions, such as in automotive construction, household appliances or entertainment electronics. With Ecovio® EA, BASF has developed a high-performance foam that is bio-based and compostable. Its excellent properties make it especially suitable for the transport packaging of valuable, heavy or fragile goods that require high shock resistance and durability.

Agricultural Solutions

We are working with farmers around the globe to improve the quality and yield of their agricultural production while taking into account societal expectations and requirements. To achieve this, we constantly invest in our development pipeline in order to expand our portfolio both in and beyond conventional crop protection – such as in biological solutions. In 2016, we invested €489 million in research and development in the Crop Protection division, representing around 9% of sales for the segment.

Our well-stocked innovation pipeline comprises products with a launch date between 2016 and 2026. With a peak sales potential1 of €3 billion, the pipeline comprises innovations from all business areas. The herbicide Engenia® is being introduced to the North American market for the 2017 growing season. It serves as a key component of dicamba and glyphosate-tolerant cropping systems for soy and cotton. We are also planning the launch of the new insecticides Inscalis® and broflanilide. Inscalis® combats piercing-sucking pests like aphids and whiteflies. An application for approval was submitted in 2016. Broflanilide is effective against chewing insects, like potato beetles and caterpillars, in specialty and field crops; use is also planned in professional pest control. With its novel mode of action, it is highly effective in low doses and will play an important role in resistance management.

We submitted the first approval applications for our new fungicide, Revysol®, in 2016. The active ingredient Revysol® is highly effective in combating a number of hard-to-control fungal infections, like Septoria tritici, an agent that causes leaf blotch in wheat. It will be offered in regionally and customer-specific product formulations and used in all important field and specialty crops worldwide. The first market launches are scheduled for the 2019 growing season upon registration with the relevant authorities.

1 Peak sales describes the highest sales value to be expected in one year. For more, see the Glossary

Oil & Gas

The Wintershall Group concentrates its innovation-related activities on improving the success rate of exploration, developing technologies for reservoirs with challenging development and production conditions, and increasing the recovery factor of reservoirs.

In the Düste crude oilfield in Germany, we tested an innovative and environmentally friendly method for increasing the reservoir’s recovery factor and have achieved positive initial results. Wintershall developed a concept within the BASF Verbund for microbial enhanced oil recovery (MEOR): We aim to use tiny life forms found in the reservoir, like microbes and microorganisms, to produce more crude oil. Fed nutrients, these multiply and produce various natural substances as metabolic products that can increase the oil recovery factor. Unlike other enhanced oil recovery (EOR) technologies, the use of microbes in MEOR can have several production-increasing effects at the same time. We also successfully managed, for the first time, to model these effects outside of the reservoir, allowing for more efficient use. A larger field test is scheduled to begin in 2017.