Creating value

- Value to Society: method for assessing economic, environmental and social impact of business activities along the value chain

- Evaluating sustainability performance to steer product portfolio

We want to measure the value proposition of our actions along the entire value chain, aware that our business activities are connected to both positive and negative impacts on the environment and society. We strive to increase our positive contribution to society and minimize the negative effects of our business activities.

In order to achieve this, we need to understand better than ever how our actions impact society and the environment. We already have many years of experience evaluating our products and processes using such methods as eco-efficiency analyses, the Sustainable Solution Steering® portfolio analysis, or BASF’s corporate carbon footprint.

Building on this, BASF has been developing a new method with external experts since 2014 to perform the first monetary assessment of the economic, ecological, and social impacts of its business activities along the value chain: the “Value to Society” approach. It enables a direct comparison between financial and nonfinancial effects on society, along with how these interact.

This transparency supports the integrated character of our actions, contributing to BASF’s long-term success. The results of these assessments are helpful in our discussions with stakeholders, in internal progress measurements, and in decision-making processes.

We contribute our approach and expertise to current debates on the monetary value of the economic, environmental and social impact of business decisions. We share our experience in networks and are involved in the corresponding standardization processes within the International Organization for Standardization (ISO).

Sustainable Solution Steering®: How BASF’s products contribute to sustainability

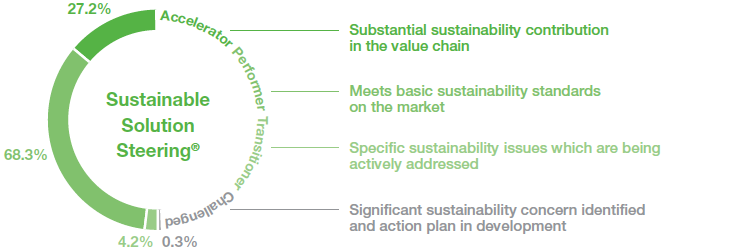

A significant lever for the targeted steering of our product portfolio, based on the sustainability performance of our products, is the Sustainable Solution Steering® method. By the end of the 2016 business year, BASF had conducted sustainability assessments and ratings for 95.9% of its entire relevant portfolio of more than 60,000 specific product applications – which account for €53.2 billion in sales. We consider the products’ application in various markets and industries. Because of increasing sustainability requirements on the market, we regularly conduct reassessments of existing product categories as well as of the relevant portfolio.

“Accelerator” products make a particular contribution to sustainability in the value chain. That is why we want to increase the proportion of sales from Accelerator products to 28% by 2020. In 2016, this figure was at 27.2%.

2020 Goal

Increase proportion of sales generated by Accelerator products

to 28%

One of our Accelerator products for the agricultural sector is Limus®, an additive for urea-based fertilizers. Using purely urea-based fertilizers means the loss of a large portion of nitrogen – one of the most important crop nutrients – through the activity of the urease enzyme. Adding Limus® inhibits this enzyme and ensures a constant supply of nitrogen. At the same time, less ammonia is released into the atmosphere. Ammonia contributes to smog, as well as to overfertilization and alternation of the ecosystem. Limus® thus leads to more consistent harvest yields while protecting the environment.

“Transitioners” are products with specific sustainability challenges that are being actively tackled. Due to the adjustment of the portfolio under evaluation, the number of these products rose in 2016. A fuel additive from our Keropur® line is one example of how we enhance the sustainability performance of our products. Such innovative fuel additives increase the efficiency of combustion engines. The result is reduced fuel consumption, and therefore fewer pollutant emissions.

Keropur® 3638 is categorized as a Transitioner because it contains a liquid hydrocarbon mixture. This hydrocarbon mixture contains naphthalene, which categorizes it as a CMR (carcinogenic, mutagenic or toxic for reproduction) substance. In order to address some of our customers’ occupational safety concerns, a research project was begun and a solution developed. Customers can now obtain the alternative Keropur® 3708, free of CMR substances.

For all products classified as “Challenged,” we aim to develop prompt plans of action, even in the case of portfolio revisions and product reassessments. These action plans can include research projects, reformulations or even replacing one product with an alternative product. At the end of 2016, action plans had been created for 100% of Challenged products.

We furthermore promoted sustainability topics in 2016 through various joint projects with partners along the value chain. One such project involved supporting the agricultural trading company AGRAVIS Raiffeisen AG, based in Münster/Hannover, in conducting calculations for the manufacture of sustainable feed mixes. BASF developed an online calculation program that compares various feed mixes for pigs using sustainability criteria along the entire value chain. The underlying eco-efficiency analysis measures various parameters like emissions to water, land use, CO2 emissions and costs. Customers can use this information to figure out how to reduce their products’ environmental impact while keeping an eye on costs. For example, a comparison between conventional and optimized feed mixes showed how impact on the environment can be significantly reduced while production costs remain nearly unchanged. Major factors here included minimizing water and land use. With new combinable feed mixes containing grain by-products and other ingredients, reductions can be attained in the use of arable land for producing feed for hogs.

More on Sustainable Solution Steering®

For more on our sustainability instruments, see:

basf.com/measurement-methods

Raw materials