Water

Water is of fundamental importance in chemical production. It is used as a coolant, solvent and cleaning agent, as well as to make our products. We are committed to its responsible use along the entire value chain and especially in our production sites’ water catchment areas. We have set ourselves a global goal for sustainable water management.

![]()

Strategy

- Sustainable water management

We aim to use water as sparingly as possible and further reduce emissions to water. To do so, we have set out a Group directive with globally applicable standards.

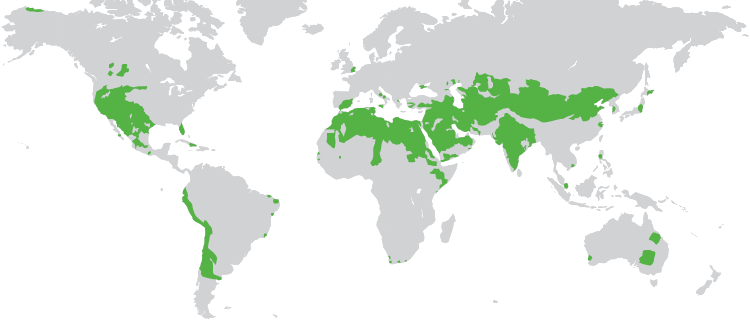

We are introducing sustainable water management at all relevant production sites. These include our major Verbund sites as well as the sites in water stress areas, or regions in which more than 60% of available water is used by industry, household and agriculture. We consider the quantitative, qualitative and social aspects of water use. We want to identify where we can improve at our sites, and use as little water as possible, especially in water stress areas.

Together with the city of Guaratinguetá, Brazil, and the Fundação Espaço ECO®, we are engaged in the restoration of the local river basin at our site in Guaratinguetá, Brazil, which provides 90% of the local population’s water supply. These efforts aim to improve water quality and increase its availability.

We offer our customers solutions that help purify water and use it more efficiently while minimizing pollution.

In order to ensure transparency in our reporting on water, we once again took part in CDP reporting in 2016. According to CDP, an international nonprofit organization, BASF is a world leader in sustainable water management and was included for the first time in CDP’s Water A List. Of the 607 companies evaluated, only 24 of them received the top score of “A” – among them, BASF. CDP’s evaluation of sustainable water management includes how transparently companies report on their water management activities and what they do to reduce risks, such as water scarcity. CDP also assesses the extent to which product developments – even at the customers of the companies under evaluation – can contribute to sustainable water management.

Water stress areas around the world

Source: Pfister et al., 2009

Global goal

By 2025, we want to introduce sustainable water management at all sites in water stress areas and at our Verbund sites, covering 93% of BASF’s entire water abstraction. We achieved 42.6% of this goal in 2016.

We pursue our goal by applying the European Water Stewardship standard, which rests on four principles: sustainable water abstraction, maintaining good water quality, preserving conservation areas, and ensuring continuous improvement processes, including in cooperation with other users.

In 2016, around 23% of our production sites were located in water stress areas. Around 1% of BASF’s total water supply was abstracted from these sites.

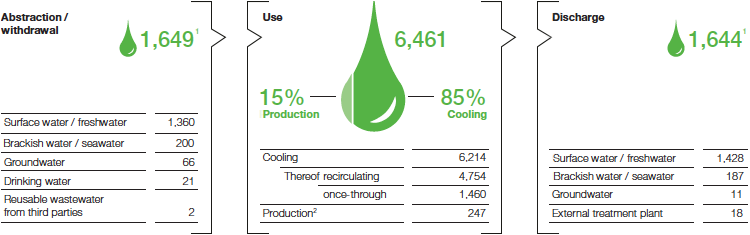

Water in the BASF Group 2016

(million cubic meters per year)

1 The difference between the volume of water drawn and the volume discharged is primarily attributable to evaporation losses during closed-circuit cooling.

2 Total from production processes, graywater, rinsing and cleaning in production

2025 Goal

100%

Introduction of sustainable water management at all production sites in water stress areas and at all Verbund sites

BASF operations excl. Oil & Gas

Water use

- Using water responsibly

Our water usage totaled 1,649 million cubic meters in 2016. This demand was covered for the most part by surface water, such as rivers and lakes. At some sites, we use alternative sources such as treated municipal wastewater, brackish water or seawater, reducing our need for freshwater.

We predominantly use water for cooling purposes (85%), after which we recirculate it back to our supply sources. We recirculate as much water as possible in order to withdraw less. Our larger sites have recooling plants that allow water to be reused several times and which reduce the temperature of used cooling water before it is discharged back into a body of water.

The supply, treatment, transportation and recooling of water is associated with a considerable energy demand. We employ various means in our efforts to minimize this as much as possible. We are constantly working to optimize our energy consumption and the amount of water we use, and to adapt to the needs of our business and the environment.

Emissions to water

- Further reduction of emissions

A total of 1,644 million cubic meters of water were discharged from BASF production sites in 2016, including 184 million cubic meters of wastewater from production. Emissions of nitrogen to water amounted to 2,900 metric tons (2015: 3,000 metric tons). We were able to achieve this improvement by optimizing processes and exchanging products, for example. Around 15,900 metric tons of organic substances were emitted in wastewater (2015: 17,300 metric tons). Our wastewater contained 23 metric tons of heavy metals (2015: 25 metric tons). Phosphorus emissions amounted to 310 metric tons (2015: 460 metric tons). Our wastewater is treated through different methods depending on the type and degree of contamination – including biological processes, oxidation, membrane technologies, precipitation or adsorption.

In order to avoid unanticipated emissions and the pollution of surface or groundwater, we create water protection strategies for our production sites. This is mandatory for all production plants as part of the Responsible Care initiative. The wastewater protection plans involve evaluating wastewater in terms of risk and drawing up suitable monitoring approaches. We use audits to check that these measures are being implemented and complied with.