Production

We never compromise on safety. For occupational and process safety as well as health protection and corporate security, we rely on comprehensive preventive measures as well as on the involvement of all employees and contractors. Our global safety and security concepts serve to protect our employees, contractors and neighbors as well as to prevent property damage and protect information and company assets. In this way, we help prevent production outages and damage to the environment.

![]()

Strategy

- New or updated goals

- Worldwide safety standards

- Enhancement of safety culture

We have set ourselves ambitious goals for safety and health protection. In 2015, we revised our goal for occupational safety, making it even more ambitious. We continue to pursue our health protection goal. We have furthermore defined a new goal for process safety.

In our guidelines and requirements, we stipulate globally mandatory standards for safety, security and health protection. A global network of experts supports us in their implementation through standardized processes. We regularly conduct audits on safety, security, health and environmental protection in order to monitor our performance. We especially promote safe conduct at work through systematic risk assessments and specific qualification measures.

Based on our corporate values, leaders serve as safety role models for our employees. Together, they contribute to the constant development of our safety culture.

Occupational safety

- Expanded occupational safety goal

- Employees and contractors worldwide receive training on safe behavior

- Directive updated for contract manufacturing

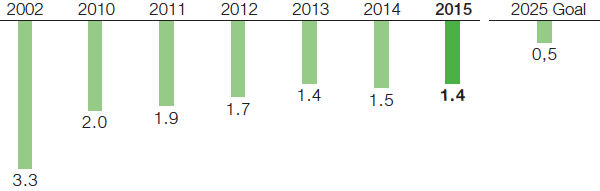

In 2015, we expanded our goal for occupational safety. We want to reduce the worldwide lost-time injury rate per million working hours to at least 0.5 by 2025 (previous 2020 goal: 0.65). In order to achieve this ambitious goal, we rely on the further development of our global safety culture, the commitment of all employees, and clearly defined safety standards. In 2015, 1.4 work-related accidents per one million working hours occurred at BASF sites worldwide (2014: 1.5), of which 8% were related to chemicals. We conduct special training in this area in order to enhance our employees’ qualifications. The work-related lost-time injury rate for contractors was 1.5 in 2015 (2014: 1.8).

Unfortunately, there were two fatal work-related accidents in 2015. In May, one employee of a contracting company succumbed to injuries sustained after falling from a scaffolding in Nanjing, China. In October, an employee in Ludwigshafen, Germany died from inhaling a low-oxygen gas mixture.

2025 Goal

≤0.5

Reduction of worldwide lost-time injury rate per one million working hours

We revised our global directive for contract manufacturing in 2015, including the new definition of audit processes on compliance with stipulated standards on safety, security, health and environmental protection.

We bolstered our safety culture in 2015 through intensive exchange and a worldwide safety initiative – the Global Safety Days – involving over 700 activities that focused on key topics like risk assessment and business travel safety. Around 75,000 employees and contractors actively participated at over 400 sites.

Going beyond legally prescribed safety instructions, we provided more than 77,000 participants around the world with training on occupational safety in 2015. For example, we trained more than 13,000 participants at our “Safety Champions Training Center” at the Ludwigshafen site in order to promote safety-conscious behavior and prevent work-related accidents.

Health protection

- 2015 focuses on nutrition

- Regular health promotion programs offered to employees

Our global health management serves to promote and maintain the health and productivity of our employees. This was supported by numerous emergency drills and health promotion measures in 2015.

We measure our performance in health protection using the Health Performance Index (HPI). The HPI comprises five components: confirmed occupational diseases, medical emergency drills, first aid training, preventive medicine and health promotion. Each component contributes a maximum of 0.2 to the total score. The highest possible score is 1.0. Our goal is to reach a value of more than 0.9 every year.

Annual goal

>0.9

Health protection Health Performance Index Maximum score 1.0

With an HPI of 0.97, we were once again able to fulfill the ambitious goal of exceeding 0.9 each year (2014: 0.91). Our 2015 global employee health campaign centered on nutrition. Numerous offers and initiatives promoting good nutrition support our employees’ health and performance, while making a contribution to BASF’s voluntary commitment to the United Nations’ Global Nutrition Compact. In 2016, the global health campaign will focus on heart attack and stroke prevention. We raise employee awareness of these topics through offers tailored toward specific target groups.

The BASF health checks form the foundation of our global health promotion program and are offered to employees at regular intervals.

Process safety

- New process safety goal

- Initiative begun to reduce process safety incidents

- Special training methods introduced

We have implemented a worldwide guideline for the safe construction and operation of our plants as well as the protection of our employees and the environment. Our safety strategy is based on prevention. That is why, when designing a new facility, we apply a five-step review system from conception to startup. It involves early consideration of the most important aspects of safety and protection of health and the environment, and monitors these in every stage of planning. We use a risk matrix to assess potential incident probability and impact, and determine the appropriate protective measures.

In order to constantly improve the safety of our production facilities worldwide, we regularly update the safety concepts in all of our plants. We review their implementation in ten-year intervals in plants with a medium to high hazard potential. The documentation of these safety reviews was standardized through software in 2014, and introduced all over the world in 2015. Moreover, we further continued to supervise the process safety management system in all regions. We completed the worldwide implementation of our requirements for explosion protection in 2015.

The number of Process Safety Incidents has served as an important key performance indicator since 2008, and is largely based on the definition set by the European Chemical Industry Council (CEFIC). This KPI mainly tracks the release of substances, in addition to fire and explosions. In 2015, we recorded 2.1 process safety incidents per one million working hours (2014: 2.21). In order to constantly improve, we set ourselves the goal in 2015 of achieving a rate of 0.5 or below by 2025. To this end, we began a worldwide initiative focusing on plant maintenance, repair and operation. We perform a detailed investigation into every incident, analyzing root causes and using the findings to derive suitable measures to take.

1 Deviation from BASF Report 2014 (2.1) due to information that became known over the course of the year

2025 Goal

≤0.5

Reduction of worldwide process safety incidents per one million working hours

To strengthen safety awareness, we developed new training methods, global recommendations for training measures in 2015 and instructed more than 19,000 participants that year.

Hazard prevention and corporate security

- Requirements implemented for emergency response and fire prevention

- SPIDER Emergency Response and Information Center Verbund enhanced in Europe

- Online training introduced for information protection

In order to ensure uniformly high standards around the world for safety, security, health and environmental protection, we implemented our requirements for emergency response planning and fire prevention in the BASF Group in 2015. To be prepared for a potential incident in our production plants, we work with specific emergency response plans that involve – depending on the situation – partners and suppliers as well as cities, communities and neighboring companies.

We regularly check our emergency systems and drill procedures with employees, contractors and local authorities. Through 224 drills and simulations in 2015, we trained the participants in our emergency response measures, such as preventive fire protection.

In 2015, we enhanced our SPIDER Emergency Response and Information Center Verbund in Europe by improving expert involvement. This enables our specialists from the site fire department, emergency medical team, site security and environmental protection around Europe to work together even more quickly and reliably across different sites. Our central emergency response supports local emergency response units around the world and around the clock. We also have been using the KATWARN system at the Ludwigshafen site since 2015, an app-based warning system that serves as an additional communication channel to inform site employees of dangerous situations.

Through audits and reviews, we monitor the implementation of measures for the comprehensive protection of our employees and the company – for example, from loss of knowledge – as well as for the worldwide protection of our sites against third-party interference. All of our security personnel have been instructed on aspects of human rights related to site security, such as the right to liberty and security of person. We also require all contractors involved in this area to comply with human rights and we conduct regular inspections. As part of investment projects, we are performing comprehensive analyses of potential risks. In 2015, we standardized the use of security services even more across our European sites in order to increase effectiveness and efficiency. Business travelers, transferees, and local employees in countries with elevated security risks are informed about appropriate protection measures and individually counseled where necessary.

Due to the increasing risks associated with the use of information technology, we started a global campaign for employees to even better protect our company knowledge. This includes a new online platform that educates employees as to how they can use available information and communications technology in a secure manner. Our worldwide network of information protection officers comprises more than 600 employees. They support the implementation of our globally mandatory requirements and conduct seminars on secure behaviors. We provided information protection instruction to more than 3,000 participants in 2015. At the end of 2015, we began the introduction of an online training module for information and knowledge protection that is mandatory for all employees.