Segment Profile

The Materials segment comprises the Performance Materials and Monomers divisions. The segment’s portfolio comprises advanced materials and their precursors for new applications and systems such as isocyanates, polyamides and inorganic basic products as well as specialties for the plastics and plastics processing industries. We aim to grow mainly organically, differentiate ourselves from our competitors through specific technology expertise, industry knowledge and customer proximity, and create maximum value in the isocyanate and polyamide value chains.

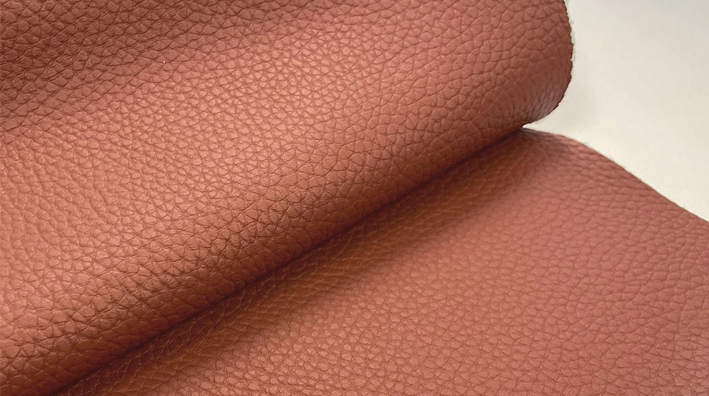

Haptex®

Haptex® is a more environmentally friendly, water-soluble polyurethane solution used in the production of synthetic leather. Among other things, Haptex®’s solvent-free production process cuts greenhouse gas emissions by around 50%. It also reduces energy consumption by more than 20% per kilo of chemicals in synthetic leather production. Moreover, Haptex® offers a wide range of applications and meets the demand for products that are eco-conscious, durable and high quality. BASF expects to grow faster than the market for solvent-based products with Haptex®. The company aims to achieve annual growth of more than 50% with the product by 2025.

Sales

€15,214 million

2020: €10,736 million

EBIT before special items

€2,418 million

2020: €835 million

|

Products |

Customer industries and applications |

|---|---|---|

Performance Materials |

Engineering plastics, biodegradable plastics, foam specialties, polyurethanes |

Automotive manufacture, electrical engineering, packaging, games, sports and leisure, household, mechanical engineering, construction, agriculture, medical technology, sanitation and water industry, solar thermal energy and photovoltaics |

Monomers |

Isocyanates (MDI, TDI), ammonia, caprolactam, adipic acid, chlorine, urea, glues and impregnating resins, caustic soda, polyamides 6 and 6.6, standard alcoholates, sulfuric and nitric acid |

Industries such as plastics, woodworking, furniture, packaging, textile, construction and automotive Use in the BASF Verbund |

Product |

Europe |

North America |

Asia Pacific |

South America, |

Annual capacity |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ammonia |

|

|

1,765,000 |

|||||||||||

Chlorine |

|

|

|

595,000 |

||||||||||

Urea |

|

|

|

545,000 |

||||||||||

Isocyanates |

|

2,620,000 |

||||||||||||

Polyamides 6 and 6.6 |

|

925,000 |

||||||||||||

Polyamide precursors |

|

1,420,000 |

||||||||||||

Propylene |

|

|

|

675,000 |

||||||||||

Sulfuric acid |

|

|

|

920,000 |

||||||||||

|

||||||||||||||